Manufacturing site

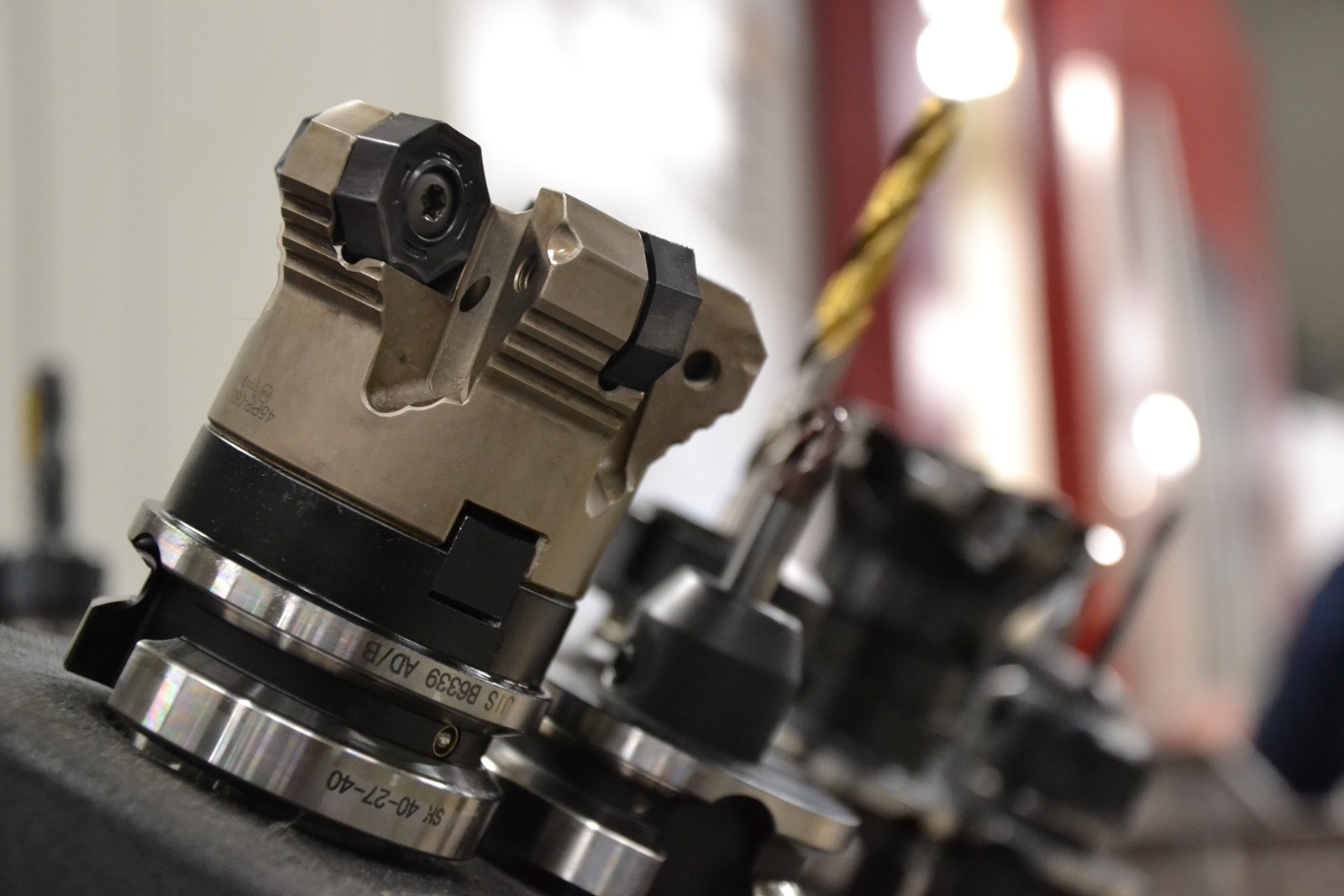

OUR OWN MANUFACTURING

We perform mechanical machining (turning, milling, grinding) in our manufacturing plant. In addition to universal machinery, cycle-controlled lathes and CNC turning centres suitable for the manufacturing of series of larger series and complicated parts, we also have a grinding and milling workshop with machining centres suitable for 3- 4- and 5-axis machining at our disposal. Moreover, we also use TopSolid and CATIA CAD/CAM systems, capable of even the simultaneous, 5-axis machining of 3D freeform surfaces. The production quality check and the end quality control of the produced parts is performed by our skilled quality inspectors, using 3D coordinate measuring machines, 3D laser scanner and manual measuring instruments.

We perform mechanical machining (turning, milling, grinding) in our manufacturing plant. In addition to universal machinery, cycle-controlled lathes and CNC turning centres suitable for the manufacturing of series of larger series and complicated parts, we also have a grinding and milling workshop with machining centres suitable for 3- 4- and 5-axis machining at our disposal. Moreover, we also use TopSolid and CATIA CAD/CAM systems, capable of even the simultaneous, 5-axis machining of 3D freeform surfaces. The production quality check and the end quality control of the produced parts is performed by our skilled quality inspectors, using 3D coordinate measuring machines, 3D laser scanner and manual measuring instruments.

Our production management engineers prepare manufacturing instructions for each product, and bar codes indicate all operations of the manufacturing process on the manufacturing order sheets. Before commencing and after finishing the individual operations, our machine operators scan the bar code relevant to the given operation, which makes it possible for us to track the current state of the manufacturing process in our SAP system, as well as to perform a subsequent calculation of the manufacturing process.

At the moment, we offer the following processing options.